SERVICES

Being in the Frontline with Terminal Operators, we provide an efficient set-up to carry out major project execution safely and effectively. Our services include but not limited to:

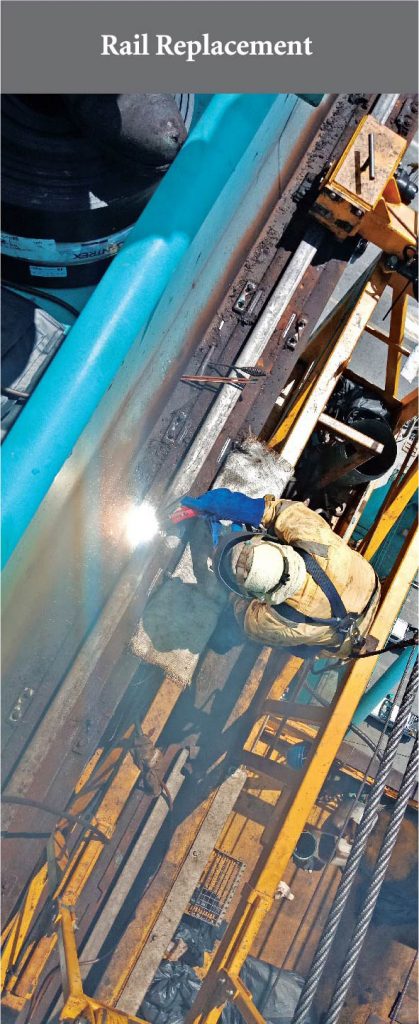

• Repair, Modification & Modernization

• Asset inspection includes life assessment survey & structural

• Accident Recovery

• Port equipment relocation & Heavy Lifts

• Equipment operation & maintenance program

PRODUCTS

With global network as well as trading house, we able to meet engineering demands to supply components and spares to support fleet of port equipment in the region. In additional with our expertise, we able to provide recommendations for the best replacement products.

We also provide value-added solutions to customer as steel fabrication (sheave, drums, guide, wheel, pins, etc).

Our products include but not limited to:

ENGINEERING PROJECTS

GPES has been involved in delivering a complete spectrum of engineering services & expertise to Seaports and Power sectors for several years. We offer different options for enhancing the performance of container handling port equipment by inspected, modified, modernized, mobilized and repaired more than 20 port cranes and equipment in the S.E.A. region.

We offer our services & expertise to our valuable customers by improving their terminals efficiency as well as maintenance scheme and benchmarking standards consists of modification, modernization, upgrading and repairs works for the port equipment, especially cranes.

With our essential network, it enabled us to source, valuing, and technical evaluation of used equipment as well as marine services to allow us to relocate the cranes and equipment in a safe environment. GPES has now evolved into a one-stop provider of container handling port equipment engineering solutions and a maintenance provider for terminals around S.E.A.

Projects for reference as shown below:

Apron replacement for 2 units of Ship-unloaders

Location : Cagayan de Oro (Philippines)

Customer : Philippines Sinter Corporation

Due to the age of the Ship Unloaders, the customer requires the apron to be replaced. The aprons (110T) are fabricated off-site and delivered by barge.

Using a heavy-lift vessel with an extension fly-jib, the existing apron is removed and then replaced with a new unit.

Apron replacement for 2 units of Ship-unloaders

Location : Cagayan de Oro (Philippines)

Customer : Philippines Sinter Corporation

Due to the age of the Ship Unloaders, the customer requires the apron to be replaced. The aprons (110T) are fabricated off-site and delivered by barge.

Using a heavy-lift vessel with an extension fly-jib, the existing apron is removed and then replaced with a new unit.

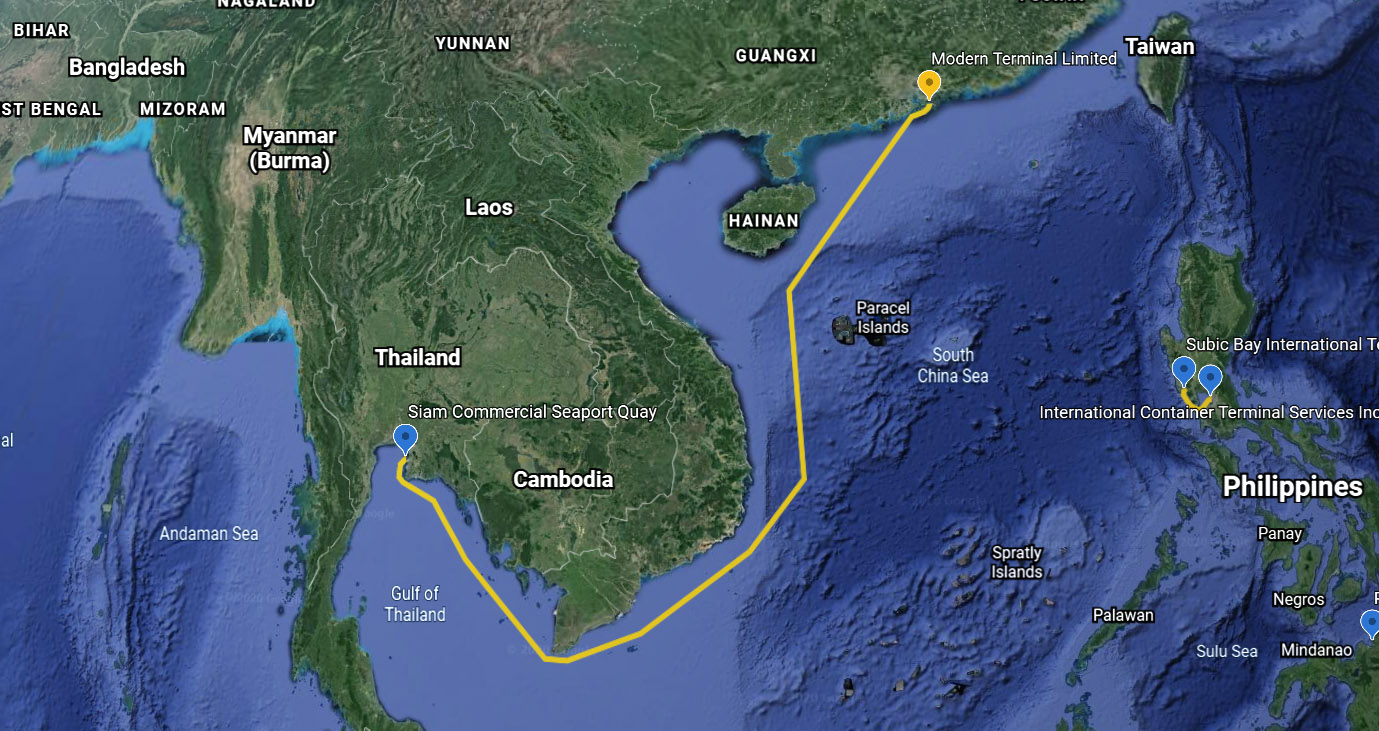

Relocation of 2 unit of Quay Crane

Location : Shanghai (China) to Sriracha (Thailand)

Customer : Siam Commercial Sea Port

As part of the sales & purchase agreement, GPES was tasked to deliver 2 units of ZPMC Quayside (QC) cranes from Shanghai Port and delivered to the Siam Commercial Seaport located at Sriracha Port.

The crane each weighing 860T was carefully transferred to the vessel using skidding method and subsequently secured to the deck for her 2400 nautical mile journey to Thailand.

The QCs are then unloaded upon arrival at the destination port also by skidding method.

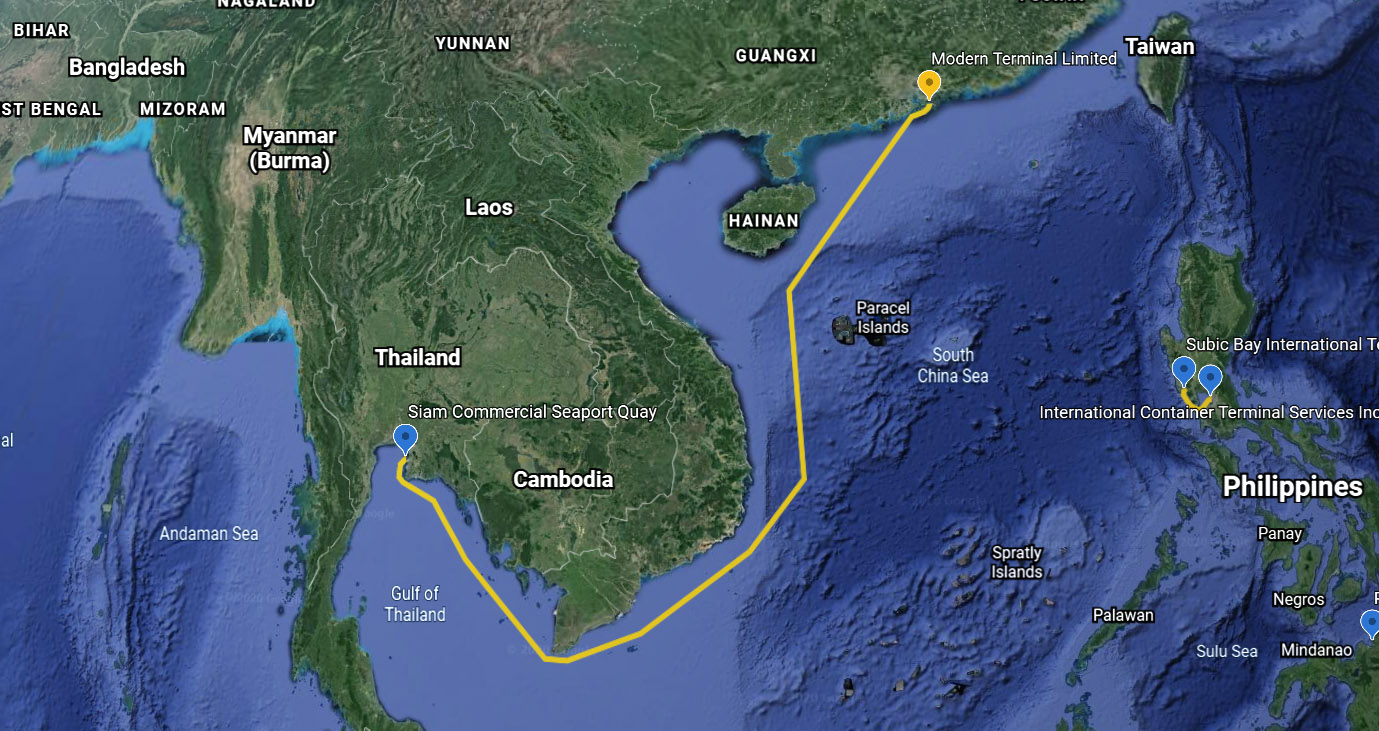

Relocation of 4 units of RTG

Location : Hong Kong to Sriracha (Thailand)

Customer : Siam Commercial Sea Port

As part of the sales & purchase agreement, GPES was tasked to deliver 4 units of MHI Rubber Tyred Gantry (RTG) cranes from Hong Kong and delivered to the Siam Commercial Sea Port located at Sriracha Port.

The crane each weighing 180T was carefully lifted using heavy-lift method from the loading quay using the vessel powerful ship’s gear (rated 450T SWL each) and subsequently secured to the deck for her 1530 nautical mile journey.

The RTGs are then unloaded upon arrival at the destination port also by heavy-lift method.

Relocation of 4 units of RTG

Location : Hong Kong to Sriracha (Thailand)

Customer : Siam Commercial Sea Port

As part of the sales & purchase agreement, GPES was tasked to deliver 4 units of MHI Rubber Tyred Gantry (RTG) cranes from Hong Kong and delivered to the Siam Commercial Sea Port located at Sriracha Port.

The crane each weighing 180T was carefully lifted using heavy-lift method from the loading quay using the vessel powerful ship’s gear (rated 450T SWL each) and subsequently secured to the deck for her 1530 nautical mile journey.

The RTGs are then unloaded upon arrival at the destination port also by heavy-lift method.

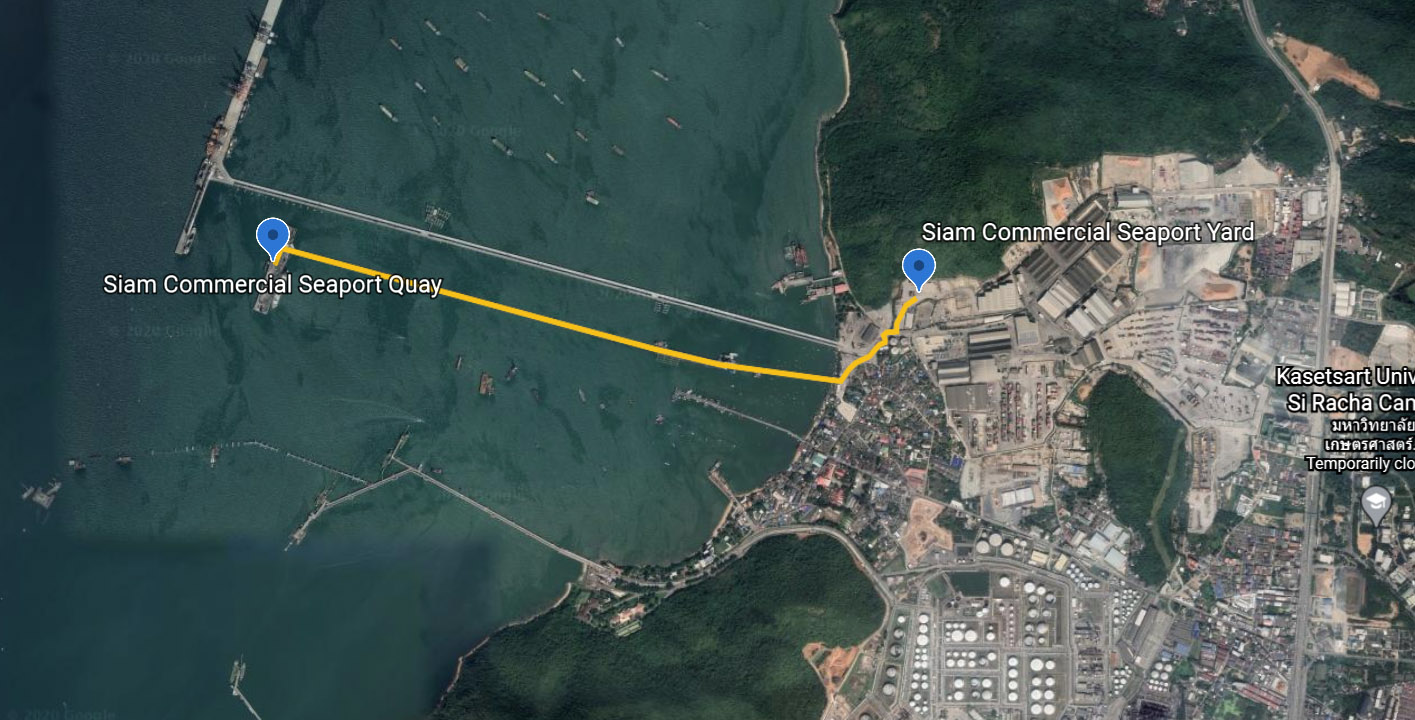

Dismantling & Re-Erection of 4 units of RTG

Location : Sriracha (Thailand)

Customer : Siam Commercial Sea Port

Upon successful discharging of the cranes, the RTGs are to be transferred to the container yard. Due to the narrow jet way, overhead power lines, narrow exit way and numerous uneven road surface, GPES decided to dismantle the crane into manageable components to enable the transfer using trucks.

After a road journey of 4.5km, the RTGs will then be re-erected back to its original condition.

2 units QC High Voltage Cable Reel Retrofit

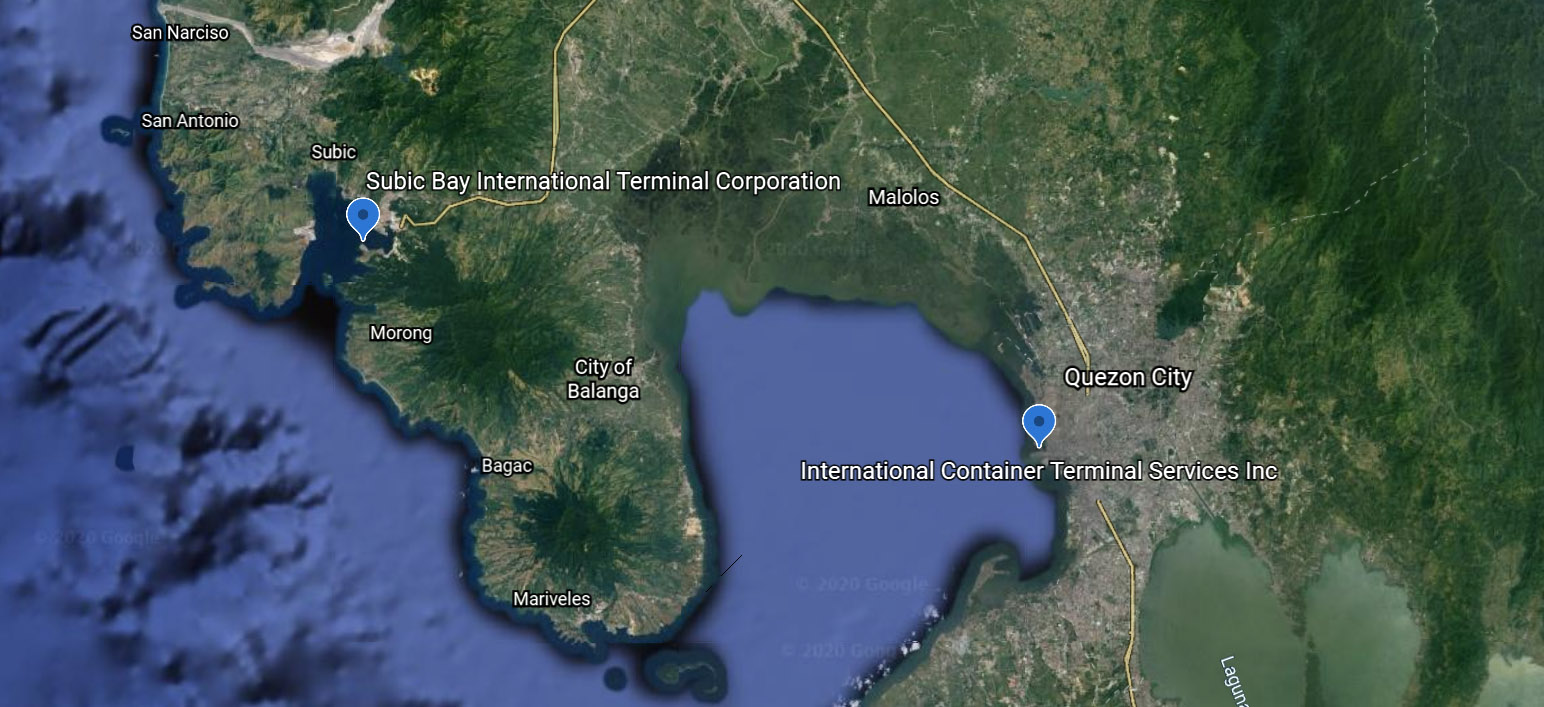

Location : Subic Bay (Philippines)

Customer : Subic Bay International Terminal Corp.

The customer intend to extend the travel distance of the QC. In order to achieve this, the high voltage trailing cable will need to be extended.

GPES is tasked to design and retrofit a new cable reel system to accommodate the extension of the trailing cable.

2 units QC High Voltage Cable Reel Retrofit

Location : Subic Bay (Philippines)

Customer : Subic Bay International Terminal Corp.

The customer intend to extend the travel distance of the QC. In order to achieve this, the high voltage trailing cable will need to be extended.

GPES is tasked to design and retrofit a new cable reel system to accommodate the extension of the trailing cable.

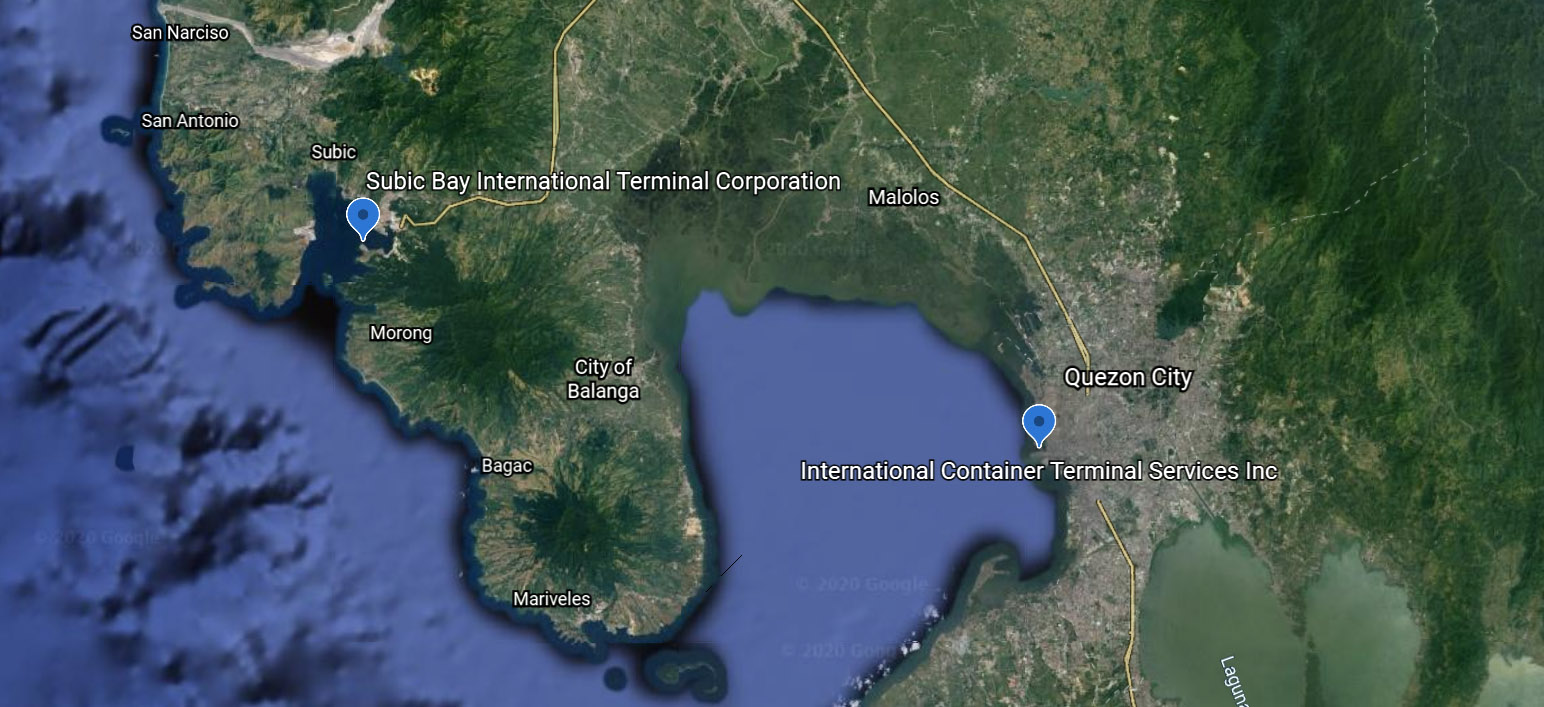

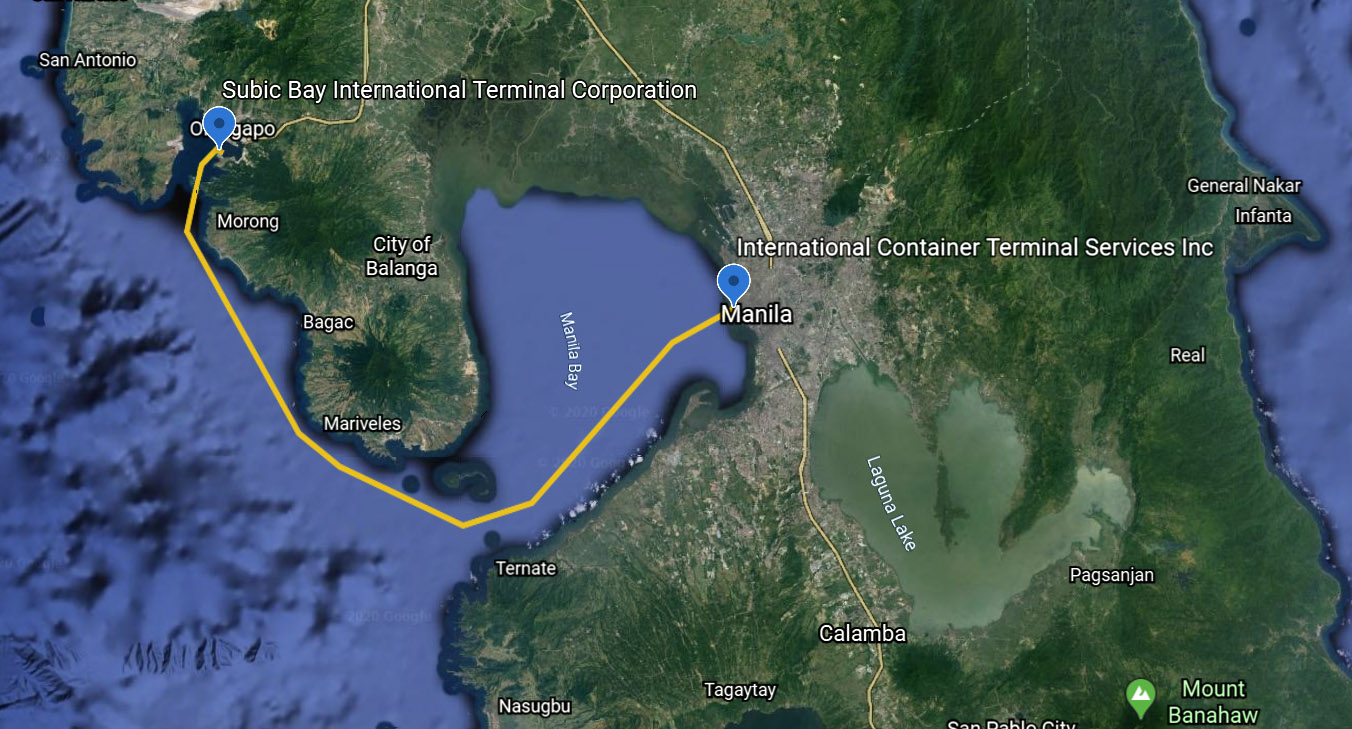

Relocation of 6 units of RTG

Location : Manila to Subic Bay

Customer : International Container Terminal Services Inc.

GPES was tasked to transfer 6 units of Noell Rubber Tyred Cranes (RTG) from Manila Terminal (ICTSI) and delivered to the Subic Bay International Terminal Corporation (SBITC).

The crane each weighing 160T was carefully transferred to the vessel using Roll-on, Roll-off (Ro-Ro) method and subsequently secured to the deck.

The QCs are then unloaded upon arrival at the destination port also by skidding method.

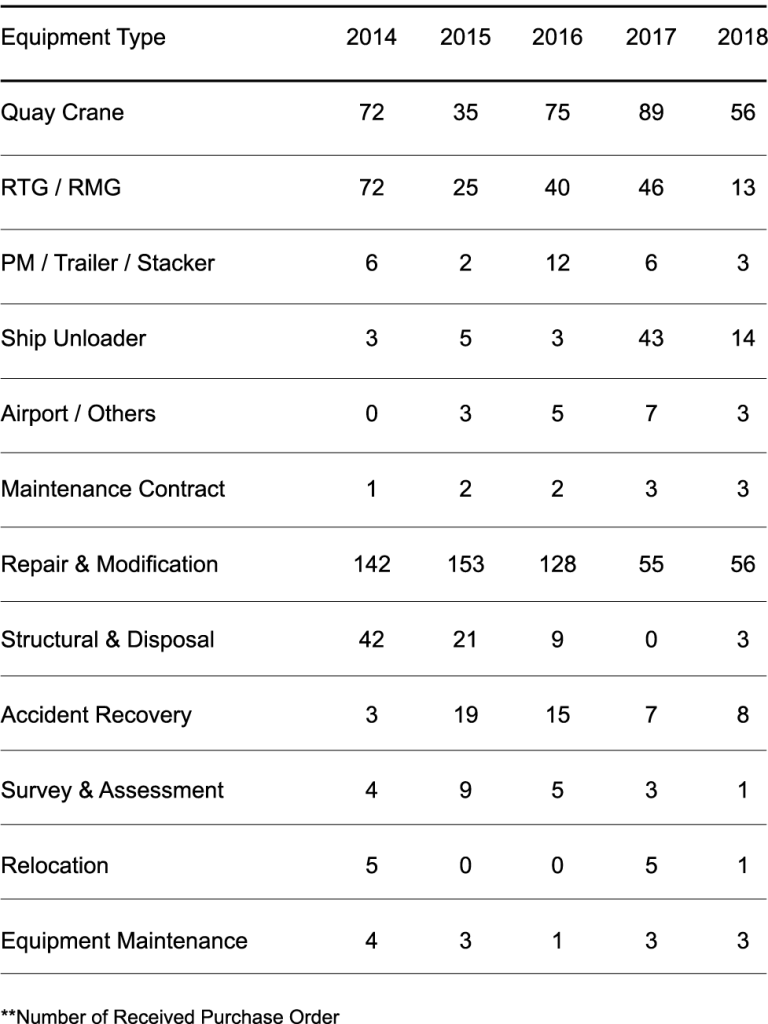

PAST PROJECTS

GLOBAL PORT ENGINEERING & SERVICES SDN BHD

13500 Permatang Pauh, Penang

Tel: +604-390 6733

Fax: +604-390 7167

Group Structure

Board of Directors

Services

Products

Engineering Projects

Past Projects

Business Partners

Award & Certificate

Copyright © 2020 GLOBAL PORT ENGINEERING & SERVICES SDN BHD

Powered by Two Fingers Design